How Are Electronics Recycled?

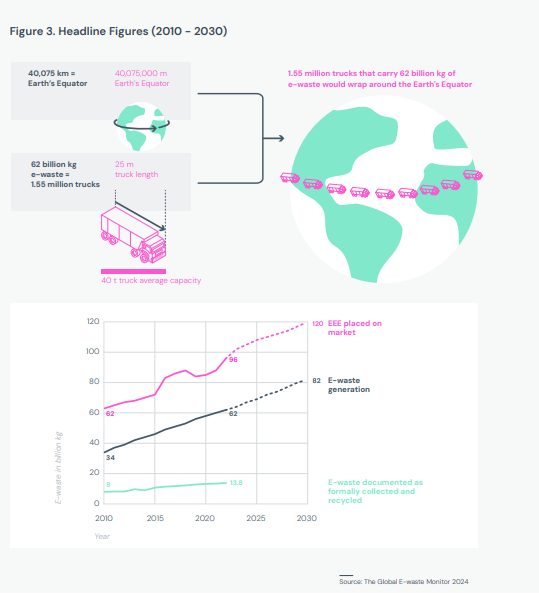

Electronic waste, or e-waste, has become one of the fastest-growing waste streams globally. Recycling your old electronics will not only help reduce the amount of landfill waste but also help reduce the environmental impact associated with manufacturing new materials.

Computers, smartphones, televisions, and household appliances are common items you can typically recycle—essentially anything that runs on electricity or batteries, contains valuable materials like metals, plastics, and glass that can be processed and reused, and has reached the end of its useful life.

In this article, we’ll cover just how easy it is to recycle your electronics and what to expect when you drop your items off at an e-waste recycling center.

The Step-by-Step Process

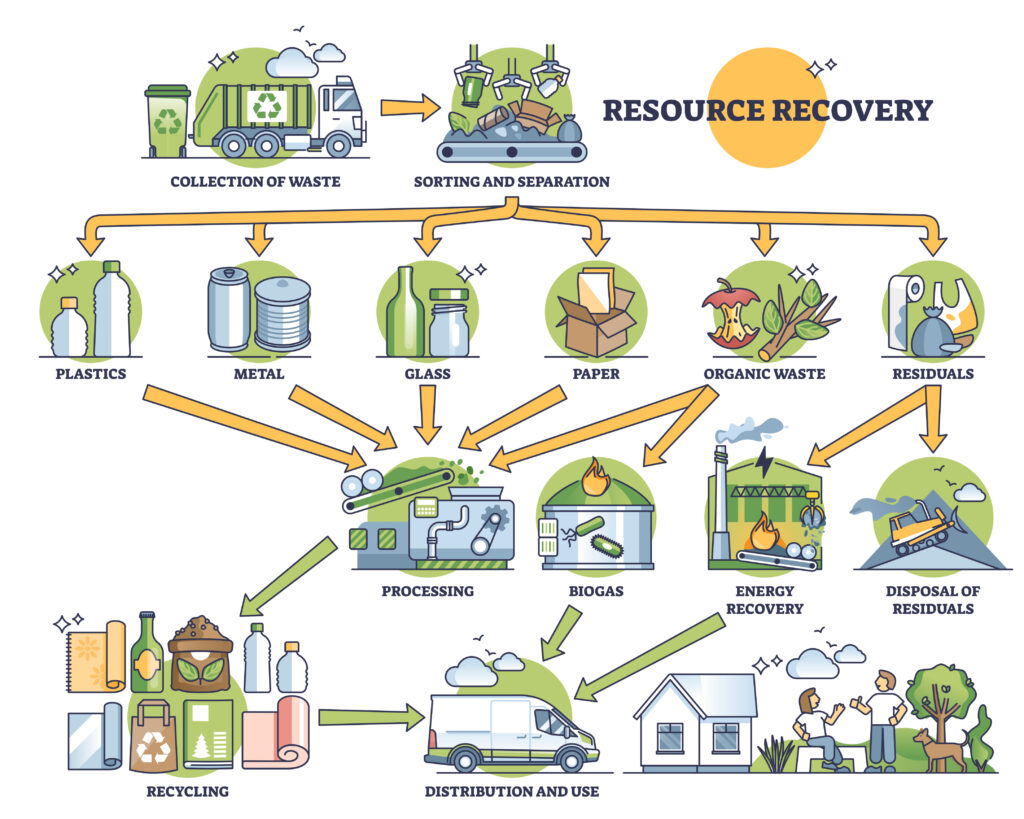

Step 1: Collection

Electronics are collected at designated drop-off points. When transporting your electronics to these drop-off points, take care to handle any items with batteries safely. If batteries are punctured, they need to be removed from the device. Batteries, especially lithium-ion, pose a fire risk if damaged. Visit this blog for more information on safe handling practices by battery type.

The good news is that this is the only process you have to do yourself—once you drop off your items, the recycling center handles the rest.

Step 2: Data Destruction

Once the recycling center receives the items, the first step is to ensure any items with hard drives are wiped to ensure secure data destruction. Several data destruction methods can be used, including physical destruction (shredding, crushing, drilling, etc.), degaussing, and software-based wiping. At High Tech Recycling, we use DoD-compliant software to thoroughly wipe hard drives.

Data destruction is necessary to ensure that reused items don’t contain sensitive information, like credit card numbers and Social Security numbers, that could otherwise compromise someone’s security.

After whatever data destruction method is performed, the recycling center will verify that the data has been destroyed and provide documentation to the individual or business that donated the electronics.

Step 3: Sorting & Dismantling

The recycling center will then manually sort the items by type and condition. Functional electronics might be refurbished and resold, while non-functional ones are recycled.

Different sorting methods are used based on the material:

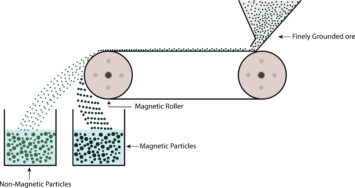

- Metals: Magnetic separation is used to distinguish ferrous (which are magnetic) from non-ferrous materials. Eddy current separation repels non-metallic materials, and is used for non-ferrous metals like aluminum and copper. Manual sorting may be used for precious metals like gold, silver, and platinum.

- Plastics: Plastics are typically submerged in water—those that float and those that sink are separated based on their density. If precise sorting is needed, centers may use near-infrared spectroscopy to identify different types of plastics based on how they reflect light.

- Glass: Glass is typically sorted manually based on its appearance and whether it is tempered, which is often used in smartphones and tablets. For some types of glass, like cathode ray tube glass, that contain lead, chemical treatments may be used to safely separate the glass from the lead content.

After materials are sorted, some components may be manually broken down with screwdrivers, pliers, and other specialized tools to prepare them for further material separation.

Electronics to be recycled are securely packed and transported to processing facilities. Recycling centers label and contain certain components to aid in identification and prevent accidents.

Step 4: Material Recovery

If items require further processing to recover materials that can be reused, the next step is material recovery.

Similar to sorting, each material has its own recovery process. The materials typically recovered include ferrous metals like iron and steel, non-ferrous metals, plastics, and glass.

Metals

Metals like copper, aluminum, and iron are melted down in smelters and then refined to purify them for reuse.

Precious metals require more specialized processes because they have a higher value. For these metals, a hydrometallurgical treatment is used. This treatment involves leaching the metals with aqua regia (gold and platinum), sulfuric acid (copper and other base metals), or sodium cyanide (gold) to dissolve solid metals and reduce them to liquid waste.

After leaching, impurities are precipitated out of the solution by adjusting the pH or adding other chemicals that react with the impurities to form solid compounds that can be filtered out.

Then, electrowinning or further chemical precipitation are used to recover the pure metal from the solution fully. In electrowinning, an electric current passes through the leach solution, causing the metals to deposit onto cathodes as a solid, pure metal. In chemical precipitation, certain chemicals are added to the solution. For gold, zinc dust is added. For copper, iron is used, and for silver, sodium chloride (salt) is used.

Plastics

Waste processing centers may have granulators, which shred plastic components into small granules, which are then cleaned to remove any impurities.

The clean granules are melted and extruded into pellets, which are used to produce new plastic products.

Glass

Glass from electronic devices is crushed into small pieces called cullet. This cullet is cleaned and treated to remove coatings and films. The clean cullet is then melted and incorporated to manufacture new glass products or used in aggregate materials for construction.

Step 5: Refurbishment & Reuse

During the sorting process, the recycling center will assess which items are suitable for refurbishment. Usually, items that are still functional or have minor issues (battery degradation, screen damage, outdated software, worn-out components, etc.) that can be easily repaired are separated from those suited for material recycling.

After repairs are paid, the devices are thoroughly cleaned and enhanced based on the condition. Cosmetic enhancements could include replacing casings or touching up paint.

Once repaired and updated, the devices are tested to ensure they meet specific functional benchmarks (testing battery life, software functionality, etc.). Devices that pass the tests are then officially “certified refurbished.”

Recycle Your Electronics Today

If you have an old phone, computer, or other electronic device, let High Tech Recycling take care of the recycling process for you. We’re a certified recycling center serving individuals and businesses in and around the metro Detroit area. You can drop off your items at our center during normal operating hours or contact us to schedule a pick-up. Please visit our website for a complete list of items we accept and do not accept.